Inspection and Testing

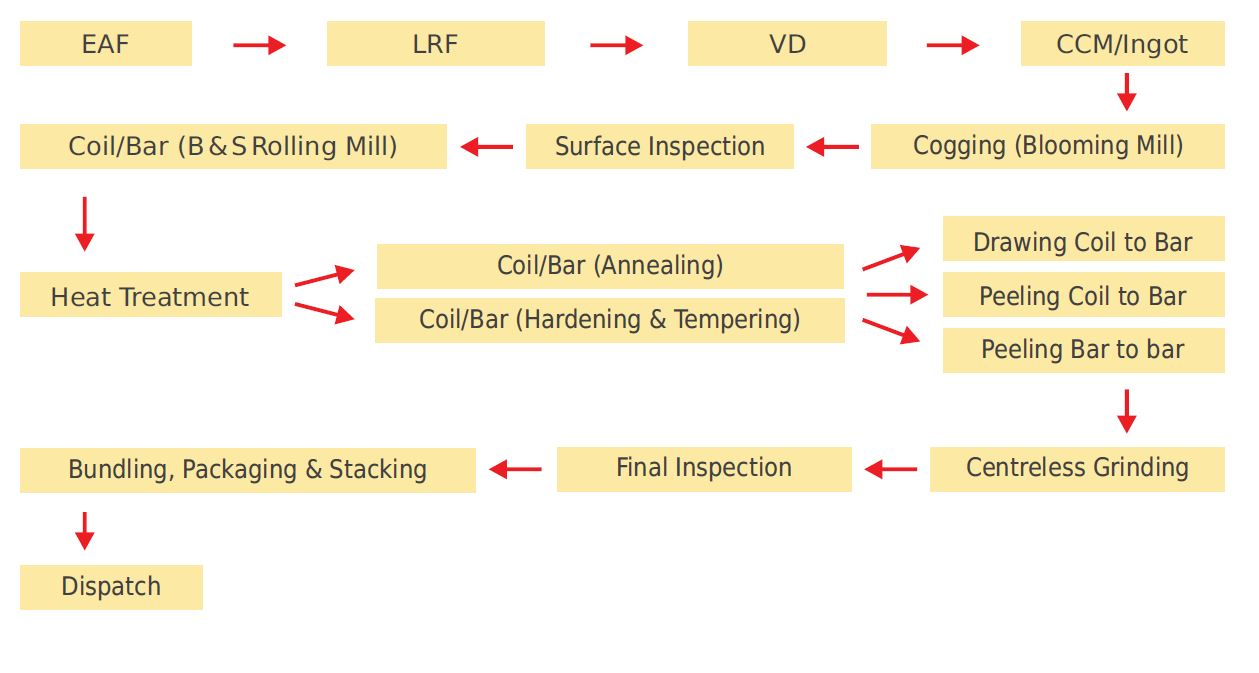

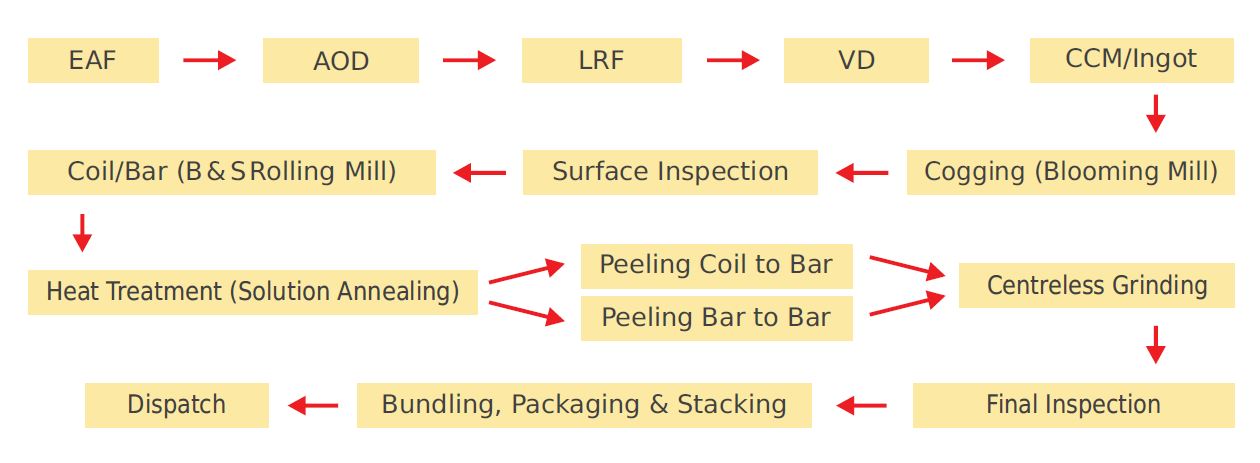

Manufacturing Route of Engine Valve Steels

Martenstic Grades

Austenitic Grades

International Standards of Valve Steels

| DIN | W.Nr | BS | JIS | SAE | IS |

|---|---|---|---|---|---|

| X45CrSi9-3 | 1.4718 | EN-52 | SUH-1 | HNV-3 | X45Cr9Si3 |

| - | - | - | SUH-11 | - | C50Cr9Si2 |

| X40CrSiMo10-2 | 1.4731 | - | SUH-3 | HNV-1 | X40Cr11Si2Mo1 |

| X85CrMoV18-2 | 1.4748 | - | - | - | - |

| X55CrMnNiN20-8 | 1.4875 | 21-2N | - | EV-12 | X55Cr21Mn8Ni2N |

| X53CrMnNiN21-9 | 1.4871 | 21-4N | SUH-35 | EV-8 | X53Cr22Mn9Ni4N |

| - | - | 21-12N | SUN-37 | EV-4 | X20Cr21Ni12N |

| X50CrMnNiNbN21-9 | 1.4882 | 21-43N | - | - | - |

| X33CrNiMnN23-8 | 1.4866 | 23-8N | - | EV-16 | X33Cr23Ni8Mn3N |

NiCr16Fe7TiAl |

2.4694 | - | SUH-751 | J-775 | - |

Supply Conditions

Chemical Composition

| Grades | C | Mn | Si | S Max | P max | Cr | Mo | Ni | W | N | Nb+Ta | Cu | Ti | Al | Fe | V |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| X45CrSi9-3(EN-52) | 0.40-0.50 | 0.60 Max | 2.70-3.30 | 0.030 | 0.040 | 8.00-10.00 | - | 0.50 Max | - | - | - | - | - | - | - | - |

| SUH-11 | 0.45-0.55 | 0.60 Max | 1.00-2.00 | 0.030 | 0.030 | 7.50-9.50 | - | 0.60 Max | - | - | - | - | - | - | - | - |

| SUH-3 | 0.35-0.45 | 0.60 Max | 1.80-2.50 | 0.030 | 0.030 | 10.00-12.00 | 0.70-1.30 | 0.60 Max | - | - | - | 0.30 Max | - | - | - | - |

| X85CrMoV18-2 | 0.80-0.90 | 1.50 Max | 1.00 Max | 0.030 | 0.040 | 16.50-18.50 | 2.00-2.50 | - | - | - | - | - | - | - | - | 0.30-0.60 |

| 21-2N | 0.50-0.60 | 7.00-10.00 | 0.25 Max | 0.030 | 0.045 | 19.50-21.50 | - | 1.50-2.75 | - | 0.20-0.40 | - | - | - | - | - | - |

| 21-4N | 0.48-0.58 | 8.00-10.00 | 0.25 Max | 0.030 | 0.045 | 20.00-22.00 | - | 3.25-4.50 | - | 0.35-0.50 |

- | - | - | - | - | - |

| 21-12N | 0.15-0.25 | 1.50 Max | 0.70-1.25 | 0.030 | 0.050 | 20.00-22.00 | - | 10.50-12.50 | - | 0.15-0.25 | - | - | - | - | - | - |

| 21-43N | 0.45-0.55 | 8-10 | 0.45 Max | 0.030 | 0.45 | 20.00-22.00 | - | 3.50-5.50 | 0.80-1.50 | 0.40-0.60 | 1.80-2.50 | - | - | - | - | - |

| 23-8N | 0.28-0.38 | 1.50-3.50 | 0.50-1.00 | 0.030 | 0.045 | 22.00-24.00 | 0.50 Max | 7.00-9.00 | 0.50 Max | 0.25-0.35 | - | - | - | - | - | - |

| Inconel 751 | 0.03-0.10 | 0.50 Max | 0.50 Max | 0.015 | 0.015 | 14.0-17.0 | 0.05 Max | Base | - | - | 0.70-1.20 | 0.50 Max | 2.00-2.60 | 1.10-1.35 | 5.00-9.00 | - |

Product Details

| Size Range | |

|---|---|

| Bright Bars | Dia 5.00 mm to 100 mm |

| Hot Rolled Annealed Wire Rod | Dia 5.00 mm to 38 mm |

| Hot Rolled Annealed Bard | Dia 15 mm to 160 mm |

| Standard Length | 4000 +50/-00 mm or as per Customer Specified Length |

| Supply Conditions | |

| Dimension Tolerance: | ISO h9, h11, +0.05, 0.05/-0.05, +0.10 & Black Bar as per IS-3739 |

| Martensitic Grades | Hot Rolled, Annealed or Hardened & Tempered |

| Drawn & Ground, Peeled or Hardened & Tempered | |

| Austenitic Grades | Hot Rolled, Solution Annealed, Peeled & Ground and Black Bar |

Mechanical Properties

| Grade | Condition | Yield Strength N/mm2 |

Tensile Strength N/mm2 |

%Elongation min |

%Reduction in Area min |

HRC |

|---|---|---|---|---|---|---|

| EN-52/X45CrSi9-3 | H & T | 700 | 900-1100 | 14 | 40 | 25-35 |

| SUH-11 | H & T | 700 | 900-1100 | 14 | 40 | 25-35 |

| SUH-3 | H & T | 700 | 900-1100 | 14 | 40 | 25-35 |

| X85CrMoV18-2 | H & T | 800 | 1000-1200 | 7 | 12 | 25 min |

| 21-2N | Solution Annealed | 550 | 900-1150 | 8 | 10 | 30-40 |

| 21-4N | Solution Annealed | 580 | 950-1200 | 8 | 10 | 30-40 |

| 21-12N | Solution Annealed | 400 | 800 | 35 | 45 | 23-25 |

| 21-43N | Solution Annealed | 580 | 950-1150 | 10 | 12 | 30 min |

| 21-8N | Solution Annealed | 550 | 850-1100 | 25 | 30 | 25 min |

| Inconel 751 | Solution Annealed | 630-850 | 1100-1300 | 12 | 20 | 32-40 |

Our Product Range